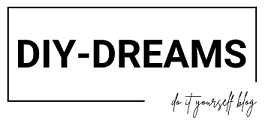

Are you interested in purchasing a laser and engraving machine but don’t know where to start? Look no further than this comprehensive guide, which covers everything you need to know about these versatile machines.

Laser and Engraving Machines: An Introduction

Laser and engraving machines use laser technology to etch, engrave, or cut a wide range of materials. These machines are capable of producing precise designs and cuts, making them a popular tool for hobbyists and professionals alike.

Laser and engraving machines come in a variety of sizes, from small desktop models to large industrial machines. They can be used to engrave or cut a variety of materials, including wood, plastic, metal, leather, and more.

Types of Laser and Engraving Machines

There are three main types of laser and engraving machines: CO2 lasers, fiber lasers, and diode lasers. Each type has its own strengths and weaknesses, and choosing the right one for your needs will depend on your specific application.

CO2 Lasers

CO2 lasers are the most common type of laser used in engraving and cutting. They use a gas-filled tube to produce a high-intensity beam of light, which is then directed through a series of mirrors and lenses before being focused onto the material to be engraved or cut.

CO2 lasers are versatile and can be used to engrave or cut a variety of materials, including wood, plastic, and fabric. They are also capable of producing very fine details and intricate designs.

Fiber Lasers

Fiber lasers are a newer type of laser technology that use a fiber-optic cable to deliver the laser beam to the material being engraved or cut. Fiber lasers are more efficient than CO2 lasers and are capable of cutting through thicker materials, such as metal.

Fiber lasers are commonly used in industrial settings for cutting and engraving metal parts and components. They are also used in the jewelry industry for engraving and marking precious metals.

Diode Lasers

Diode lasers are the smallest and least powerful type of laser used in engraving and cutting. They are often used in low-power desktop models for engraving small items like keychains and jewelry.

Diode lasers are inexpensive and easy to use, making them a popular choice for hobbyists and small businesses.

Choosing the Right Laser and Engraving Machine

When choosing a laser and engraving machine, there are several factors to consider. These include:

- Material: What type of material will you be engraving or cutting? Different machines are better suited for different materials.

- Size: What size pieces will you be working with? Make sure to choose a machine that can accommodate your needs.

- Power: How much power do you need? More powerful machines can engrave or cut through thicker materials.

- Budget: What is your budget? Laser and engraving machines can range in price from a few hundred dollars to tens of thousands of dollars.

How to Use a Laser and Engraving Machine

Using a laser and engraving machine can be intimidating at first, but with a little practice, it’s easy to get the hang of it. Here are some general steps for using a laser and engraving machine:

- Choose your material and design: Decide what material you want to engrave or cut and what design you want to create.

- Set up the machine: Follow the manufacturer’s instructions to set up the machine and load your material.

- Configure the settings: Adjust the laser settings based on the material you’re using and the design you want to create.

- Start the machine: Press the start button and let the machine do its work.

Maintenance and Safety Tips for Laser and Engraving Machines

Like any piece of machinery, laser and engraving machines require regular maintenance to keep them running smoothly. Here are some tips for maintaining your laser and engraving machine:

- Clean the machine regularly: Dust and debris can accumulate on the machine’s lens and mirrors, which can affect the quality of your engravings or cuts. Use a soft cloth to gently clean the lens and mirrors regularly.

- Check the alignment: Over time, the machine’s alignment can shift, which can affect the quality of your engravings or cuts. Check the alignment regularly and make adjustments as needed.

- Replace parts as needed: Some parts, such as the lens or mirror, may need to be replaced periodically. Check the manufacturer’s recommendations for replacement intervals.

- Follow safety protocols: Laser and engraving machines can be dangerous if not used properly. Always follow the manufacturer’s safety guidelines and wear appropriate protective gear, such as goggles and gloves.

FAQs

- What materials can be engraved or cut using a laser and engraving machine?

- Laser and engraving machines can be used to engrave or cut a variety of materials, including wood, plastic, metal, leather, and more.

- How do I choose the right laser and engraving machine for my needs?

- When choosing a laser and engraving machine, consider factors such as the materials you’ll be working with, the size of your projects, your budget, and the machine’s power.

- Is it difficult to use a laser and engraving machine?

- Using a laser and engraving machine can be intimidating at first, but with practice and following manufacturer’s instructions, it is easy to learn.

- How much do laser and engraving machines cost?

- The cost of laser and engraving machines varies widely depending on the size, power, and features of the machine. Prices can range from a few hundred dollars to tens of thousands of dollars.

- Are laser and engraving machines safe to use?

- Laser and engraving machines can be dangerous if not used properly. Always follow the manufacturer’s safety guidelines and wear appropriate protective gear.

- What maintenance is required for laser and engraving machines?

- Laser and engraving machines require regular cleaning, alignment checks, and parts replacement as needed.

Conclusion

Laser and engraving machines are versatile tools that can be used for a wide range of applications, from hobby projects to industrial manufacturing. By considering your specific needs and taking the necessary safety precautions, you can choose the right machine for your needs and create high-quality engravings and cuts with ease.

If you’re interested in purchasing a laser and engraving machine, make sure to do your research and choose a reputable manufacturer. And remember to follow the maintenance and safety tips outlined in this guide to keep your machine running smoothly for years to come.